There are four types of basic strap configurations:

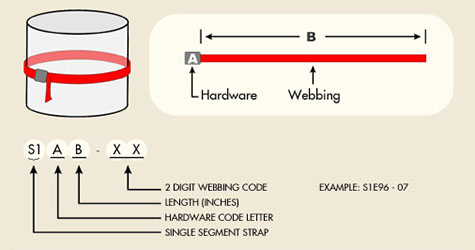

Single Segment strap (S1) – Strap made with securing/adjusting hardware on one end and specified length of webbing on the other. (see diagram above; also straps S2, S3, and S4 for additional options). Straps are made per customer’s specs, so submit a quote and a Cargo Systems Representative will assist you!

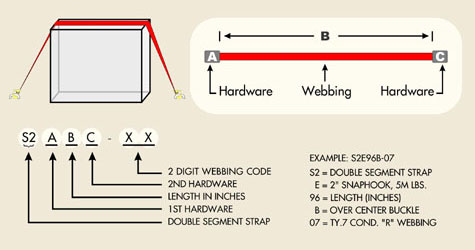

Single Segment strap (S2) – Strap made with securing and adjusting hardware on the ends, and specified length of webbing between. (see diagram above; also straps S1, S3, and S4 for additional options). Straps are made per customers specs, so submit a quote and a Cargo Systems Representative will assist you!

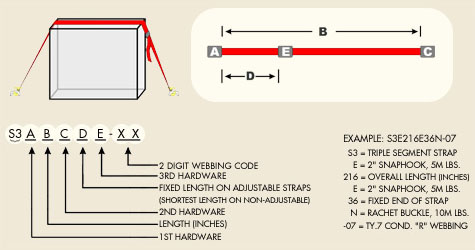

Single Segment strap (S3) – Strap made with adjusting hardware in the middle of the webbing, and specified length of webbing on both sides. (see diagram above; also straps S1, S2, and S4 for additional options). Straps are made per customer specs, so submit a quote and a Cargo Systems Representative will assist you!

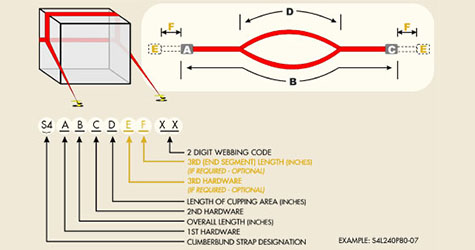

Single Segment strap (S4) – Strap made with either securing/adjusting hardware on both ends, and specified length of webbing between with a “cupping loop” to secure cargo. (see diagram above; also straps S1, S2, and S3 for additional options). Straps are made per customer specs, so submit a quote and a Cargo Systems Representative will assist you!

Hardware Webbing Codes

| Code | Width | Material | Breaking Strength |

| -07 | 1.75″ | Nylon | 6,000 lb. |

| -09 | 3″ | Nylon | 9,000 lb. |

| -17 | 1″ | Nylon | 2,500 lb. |

| -22 | 1.75″ | Nylon | 9,500 lb. |

| -32 | 2″ | Polyester | 12,000 lb. |

| -33 | 3″ | Polyester | 18,000 lb. |